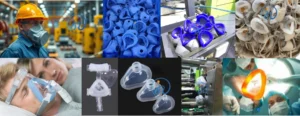

Overmolding is a manufacturing process where one material is molded over another, creating a seamless bond between the two components. In the case of a half-mask, often used in respiratory protection or safety equipment, Liquid Silicone Rubber (LSR) is a preferred material for overmolding. Its flexibility, hypoallergenic properties, and durability make it ideal for ensuring a tight, comfortable fit around the face.

Key Steps in LSR Overmolding for Half-Masks

- Base Material Selection

- The substrate or base material, commonly thermoplastics like polycarbonate (PC), is chosen for its structural rigidity. This material forms the framework or skeleton of the half-mask.

- Compatibility with LSR is critical to achieve a strong chemical or mechanical bond between the two materials.

- Mold Design

- A precise mold is required to ensure proper alignment of the LSR over the base material.

-

- Multi-cavity molds are often used for production efficiency, and venting systems are integrated to eliminate air pockets during the molding process.

- Material Preparation

- LSR is supplied as a two-component liquid (A and B) that is mixed in a specific ratio. Additives like pigments can be incorporated if color customization is required.

- Injection Process

- The base material is placed in the mold, either manually or through automation.

- The LSR is injected into the mold at controlled temperatures and pressures. The material flows around the substrate, bonding as it cures.

- The curing process typically occurs at high temperatures (150–200°C) within a few seconds to minutes, depending on the mask design and material properties.

- Demolding and Post-Processing

- Once the LSR has cured, the half-mask is removed from the mold. Automation is often used to ensure consistency and efficiency in high-volume production.

- Flash or excess material is trimmed, if necessary, though precise mold design can minimize this need.

Advantages of LSR Overmolding for Half-Masks

- Seamless Integration: LSR overmolding creates a watertight and airtight seal, essential for respiratory masks.

- Enhanced Comfort: The soft and flexible LSR layer conforms to the user’s face, improving comfort and wearability.

- Durability: LSR is resistant to extreme temperatures, UV radiation, and chemicals, ensuring the mask’s longevity.

- Hygiene: LSR is hypoallergenic and can be sterilized, making it suitable for medical and safety applications.

Applications

- Respiratory Masks: Used in healthcare, industrial safety, and personal protective equipment.

- Diving or Snorkeling Gear: Half-masks with LSR provide a tight seal against water ingress.

- Sports Equipment: Protective masks for athletes often use LSR for added comfort and shock absorption.