Liquid Silicone Rubber (LSR) is a versatile, high-performance material increasingly used across industries such as medical, automotive, electronics, and consumer products. For engineers and procurement specialists seeking durable, biocompatible, and high-purity materials, liquid silicone offers unmatched advantages. This comprehensive guide explores the key properties, processing techniques, and application scenarios of LSR, helping decision-makers make informed choices.

What Is Liquid Silicone Rubber (LSR)?

Liquid Silicone Rubber is a two-part platinum-cured elastomer known for its flowability and thermal stability. Unlike High Consistency Rubber (HCR), LSR has a low viscosity and is ideal for injection molding, enabling high-volume, precision manufacturing.

Each component (Part A and Part B) contains reactive ingredients that cure quickly when mixed and exposed to heat. This process forms a durable elastomer suitable for complex and high-tolerance parts. A key distinction is LSR’s automated process compatibility, making it especially attractive for industries demanding consistency and cleanliness.

Key Properties of Liquid Silicone

Liquid silicone exhibits a unique combination of mechanical and chemical properties:

- High Transparency & Flexibility: Ideal for soft-touch or transparent components like baby bottle nipples or LED housings.

- Biocompatibility: Safe for medical and food-contact applications, often certified to USP Class VI and FDA standards.

- Thermal Stability: Functions reliably from -50°C to +200°C, with temporary resistance up to 250°C.

- Chemical Resistance: Withstands alcohols, acids, and detergents without degradation.

- Electrical Insulation: Excellent dielectric strength makes LSR perfect for connectors and gaskets in electronics.

These properties make liquid silicone an ideal material for demanding environments requiring hygiene, flexibility, and durability.

Main Applications of LSR

LSR’s adaptability has led to wide adoption in several industries:

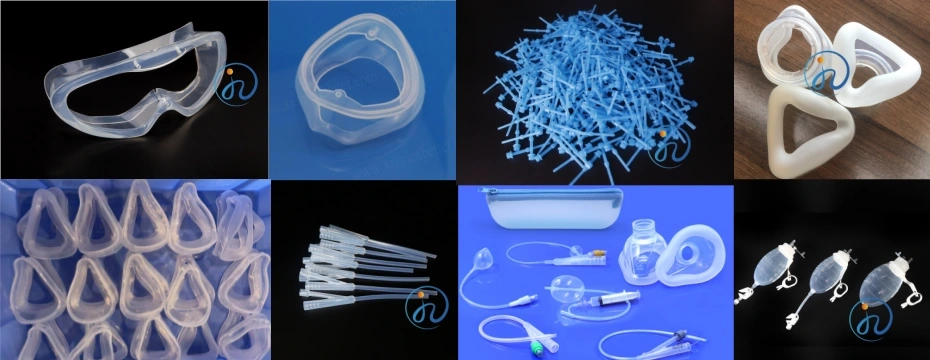

Medical

- Catheters, seals, valves, and wearable devices

- Benefits: biocompatibility, sterilizability, softness

Automotive

- Grommets, O-rings, and sensor seals

- Benefits: heat and oil resistance, dimensional stability

Consumer Electronics

- Protective phone cases, keypads, cable connectors

- Benefits: durability, precision molding, shock absorption

Baby & Food Products

- Pacifiers, baking molds, kitchenware

- Benefits: food-grade certification, odorless and tasteless

Liquid silicone not only meets industry-specific technical requirements but also supports rapid prototyping and scalability.

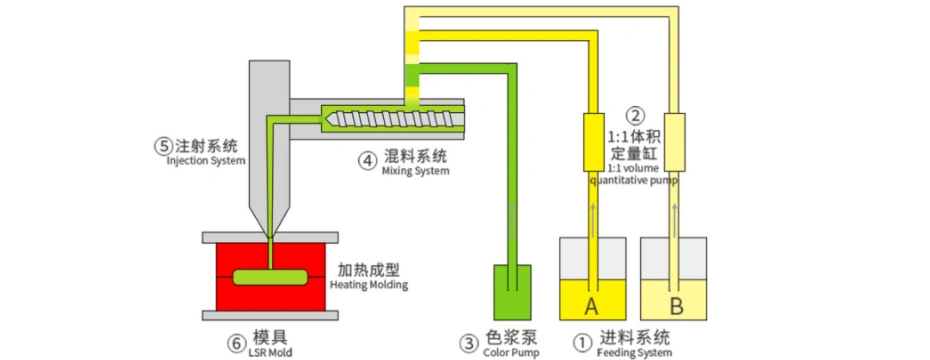

Liquid Silicone Injection Molding Process

Injection molding is the most efficient method to process LSR. The process involves:

- Metering & Mixing: Precise mixing of Part A and Part B with optional color or additive dosing.

- Injection: The mixture is injected into a pre-heated mold.

- Curing: Heat initiates curing within seconds to minutes.

- Demolding: The part is ejected automatically.

🛠️ Key Benefits of LSR Molding:

- Fully automated, suitable for 24/7 production

- Little to no material waste

- Short cycle times

- Consistent part quality, ideal for micro-features

Compared to compression or transfer molding, LSR injection molding offers higher efficiency and better surface finish, which are critical for cleanroom manufacturing and precision engineering.

Why Choose LSR for Your Product?

Procurement and design teams often weigh cost vs. performance. Here’s how liquid silicone delivers superior ROI:

- Long-Term Durability: Resists cracking, yellowing, or aging

- High Throughput: Fast cycles reduce production cost

- Automation-Ready: Compatible with robotic demolding and inline quality control

- Cleanroom Compatibility: Meets the standards for medical and electronics manufacturing

- Regulatory Compliance: FDA, RoHS, ISO certifications

When consistency and reliability are mission-critical, liquid silicone is a smart investment.

How to Select the Right LSR Supplier

Choosing a reliable LSR manufacturing partner is essential. Consider the following factors:

- Experience: Years of specialization in liquid silicone injection molding

- Certifications: ISO 9001, ISO 13485, FDA, REACH, RoHS

- Customization: Ability to develop molds and tailored silicone formulations

- Technical Support: Design-for-manufacturing (DFM) consultation and prototyping services

- Production Scale: Can they handle both low and high-volume runs?

🔍 About Jiaze Silicone

At Jiaze Silicone, we specialize in custom LSR components for medical, consumer, and industrial applications. Our in-house mold development, rapid prototyping, and cleanroom molding capabilities ensure you get precise, high-quality results every time.

Liquid Silicone vs. Other Elastomers

Here’s how LSR stacks up against common alternatives:

| Feature | LSR | TPE | EPDM |

|---|---|---|---|

| Biocompatibility | Excellent | Moderate | Poor |

| Heat Resistance | Up to 200°C | ~120°C | ~150°C |

| Chemical Resistance | Strong | Moderate | Limited |

| Transparency | Yes | No | No |

| Molding Precision | High | Moderate | Low |

| Cost | Moderate | Low | Low |

Conclusion: LSR offers superior technical benefits, especially where hygiene, clarity, and durability are needed.

Conclusion

Liquid Silicone Rubber is more than just a flexible material—it’s a manufacturing enabler. From high-volume production to critical medical components, LSR provides unmatched consistency, biocompatibility, and performance.

For engineers and procurement professionals, investing in LSR means reducing long-term risk and increasing product value. Whether you need a custom solution or rapid prototyping, Jiaze Silicone is ready to support your innovation.

Ready to start your project? Contact us for a free consultation or request a sample today.