Summary of the Process

Two-shot injection molding, additionally called dual-shot or multi-shot molding, is an advanced manufacturing procedure that enables for the creation of facility, multi-material parts in a single production cycle. This technique entails the sequential injection of 2 different products right into a mold and mildew, resulting in a solitary, incorporated component made up of two distinct layers or areas.

Step-by-Step Process

The two-shot injection molding procedure generally entails the adhering to following actions:

1. First Material Injection

In the initial stage, the first product, frequently described as the substrate, is infused into a mold tooth cavity. This product develops the base layer or core of the end product. As soon as the substrate has actually been injected and sufficiently cooled, the mold opens to disclose the partly completed part.

2. Build Rotation or Transfer

After the very first product has actually been injected and cooled, the mold and mildew go through a rotation or transfer procedure. This step is crucial as it rearranges the substrate right into a brand-new cavity where the 2nd material will certainly be infused. The repositioning can be attained via different mechanisms, consisting of rotating platens, sliding cores, or robot arms.

3. Second Material Injection

When the substratum is in position, the second material is infused right into the mold and mildew. This product usually creates the external layer or additional functions of the final part. The second material bonds with the substratum, either through chemical adhesion or mechanical interlocking, producing a cohesive, multi-material component.

4. Cooling and Ejection

After the 2nd product has been injected and adequately cooled, the mold opens, and the finished component is ejected. The end product is now a solitary, integrated piece made from 2 distinctive products, each adding to the overall functionality and appearance of the part.

Benefits of Two-Shot Injection Molding

Improved Product Design

Two-shot shot molding permits the production of complicated, multi-material elements in a single manufacturing procedure. This capability makes it possible for designers to integrate various materials with distinctive properties, such as rigidness and versatility, in a solitary component. The result is an extra practical and aesthetically pleasing product.

Improved Product Integrity

By molding 2 products together, two-shot shot molding makes sure a strong bond between the different materials, enhancing the total structural honesty of the end product. This method reduces the risk of a part failing as a result of splitting up or weak bonding, which prevails in conventional setting-up techniques.

Cost Efficiency

Two-shot injection molding can result in substantial expense savings. The process minimizes the requirement for second procedures, such as assembly and bonding, which can be labor-intensive and pricey. In addition, by producing components in a single cycle, producers can achieve higher production prices and lower per-unit expenses.

Minimized Assembly Time

Given that two-shot injection molding integrates several products into one part during a solitary molding cycle, it gets rid of the demand for additional setting up steps. This reduction in assembly time equates to quicker manufacturing cycles and quicker time-to-market for brand-new products.

Boosted Product Durability

The combination of various products in a solitary molding procedure can improve the durability and performance of the end product. As an example, integrating a tough plastic with a soft elastomer can give both structural assistance and shock absorption, making the product a lot more resilient to deterioration.

Design Flexibility

Two-shot shot molding uses unparalleled style adaptability, permitting the unification of functions such as shade variations, textured surface areas, and ergonomic grasps directly into the shaped component. This versatility can lead to more ingenious item designs and boosted user experiences.

Environmental Benefits

By minimizing the demand for secondary assembly procedures and lessening product waste, two-shot shot molding can have a favorable impact on the environment. The procedure is more effective and can result in a decrease in the overall carbon footprint of the production process.

Applications of Two-Shot Injection Molding

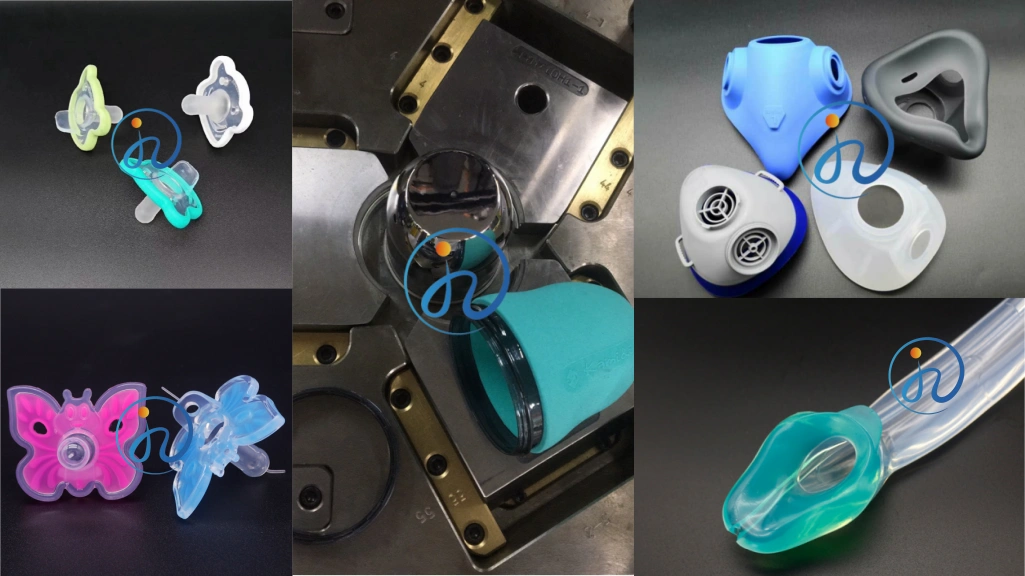

Consumer Products

Two-shot shot molding is extensively utilized in the customer items sector. This modern technology permits the creation of complicated, multi-material parts in a single production process. Products such as toothbrushes, razors, and kitchen area tools often profit from this technique, as it allows the combination of soft and hard products, giving both comfort and capability.

Automotive Industry

In the automotive market, two-shot injection molding plays a crucial role in manufacturing parts that need both visual allure and sturdiness. Components like control panel buttons, handles, and seals can be produced with complex designs and multiple materials, boosting both the functionality and the visual allure of the car’s interior.

Medical Devices

The medical market depends heavily on the accuracy and effectiveness of two-shot injection molding. Medical tools such as syringes, medical devices, and analysis devices usually call for elements made from various products to ensure performance and safety. This modern technology permits the production of these complicated parts with high precision and consistency.

Electronic devices

The electronics market benefits considerably from two-shot shot molding, especially in the manufacturing of real estate and rooms for gadgets. This process allows for the assimilation of various materials, such as combining rigid plastics with rubberized grips, which enhances the sturdiness and user experience of electronic devices like remote controls, mobile phones, and video gaming controllers.

Industrial Applications

Two-shot shot molding is also made use of in numerous commercial applications. Elements for machinery, devices, and devices typically require a combination of products to satisfy certain efficiency requirements. This modern technology permits the manufacturing of durable, multi-material components that can stand up to harsh operating conditions.

Choosing the Right Materials for Two-Shot Injection Molding

In the realm of two-shot injection molding, picking the appropriate products is critical to attaining the preferred item’s top quality and performance. The selection of products directly affects the toughness, appearance, and performance of the end product. Below, we will explore the essential factors to consider and generally used products in two-shot shot molding.

Typically Used Materials

Below is a table detailing a few of the typically made use of materials in two-shot shot molding in addition to their main attributes:

| Material | Key Attributes | Normal Applications |

|---|---|---|

| Polycarbonate (COMPUTER) | High influence resistance, quality | Automotive parts, electronic housings |

| Thermoplastic Elastomers (TPE) | Flexibility, rubber-like appearance | Soft-touch holds over-molded manages |

| Acrylonitrile Butadiene Styrene (ABS) | High stamina, great coating | Consumer electronic devices, toys |

| Polypropylene (PP) | Chemical resistance, low density | Medical tools, packaging |

| Polyamide (Nylon) | High resilience, put on resistance | Gears, mechanical elements |

Product Pairing Strategies

Effective material pairing is important for successful two-shot injection molding. Here are some methods:

- Soft-Hard Pairing: Combining a soft product (like TPE) with a hard product (like a computer) can improve grip and functional designs.

- Color Contrast: Using products of various shades can produce visually attractive items with unique functions.

- Functional Layering: Pairing products with different buildings can include functionality, such as incorporating an inflexible core with a versatile exterior.

To conclude, the selection of products in two-shot injection molding is an essential action that calls for cautious factors to consider of compatibility, residential properties, and application demands. By recognizing the attributes of numerous products and utilizing effective pairing strategies, suppliers can enhance the efficiency and looks of their items.

FAQs About Two-Shot Injection Molding

What is two-shot injection molding?

Two-shot injection molding, also known as dual-shot, multi-shot, or 2K injection molding, is a sophisticated manufacturing process that allows for the creation of complex, multi-material components in a single production cycle. It involves the sequential injection of two different materials into a mold to form a single, integrated part.

How does two-shot injection molding work?

The process involves injecting the first material into a mold to form the initial part. The mold is then rotated or transferred to a second station, where the second material is injected to complete the part. This method eliminates the need for secondary operations, ensuring efficient production of multi-material components.

What are the benefits of two-shot injection molding?

Two-shot injection molding LSR offers numerous benefits, including enhanced product design, improved product integrity, cost efficiency, reduced assembly time, enhanced product durability, design flexibility, and environmental benefits.

What industries commonly use two-shot injection molding?

Two-shot injection molding is widely used in various industries, including consumer products, automotive, medical devices, electronics, packaging, and industrial applications. Each industry benefits from the ability to combine different materials and create complex components.

What materials are commonly used in two-shot injection molding?

Common materials include Polycarbonate (PC), Thermoplastic Elastomers (TPE), Acrylonitrile Butadiene Styrene (ABS), Polypropylene (PP), and Polyamide (Nylon). These materials are chosen based on their compatibility, thermal properties, mechanical properties, aesthetics, and cost.

What are the key components of a two-shot injection molding machine?

The key components include two separate injection units for different materials, a specialized mold capable of handling two materials or colors, and a rotary platen or transfer system to shift the initial part to the second injection station.

What are the key considerations for successful two-shot injection molding?

Key considerations include material compatibility, precise mold design, and accurate process control. These factors ensure proper bonding, high-quality results, and efficient production cycles.

How does two-shot injection molding enhance product design?

This process allows for the integration of different materials with distinct properties, such as rigidity and flexibility, in a single part. It enables the creation of more functional and aesthetically pleasing products.

Why is two-shot injection molding cost-efficient?

The process reduces the need for secondary operations like assembly and bonding, which can be labor-intensive and costly. It also allows for higher production rates and lower per-unit costs by producing parts in a single cycle.