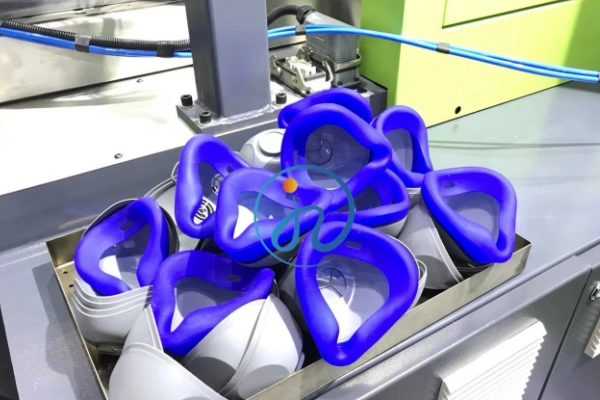

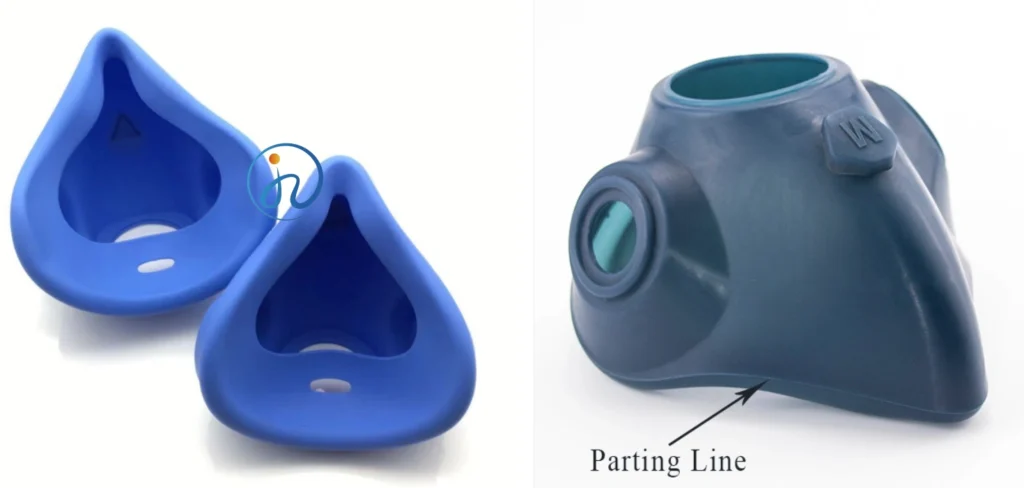

Silicone half-face respirators also called half-face masks, silicone face masks, and silicone rubber mask respirators, are made of food-grade or medical-grade liquid silicone rubber and produced by liquid silicone rubber injection molding (LIM).

How to choose the right molding for your silicone face mask?

| Item | LIM liquid silicone injection molding | compression molding |

| Mold cost | High | Common |

| Unit cost | Relatively Low | High |

| Quality | Prefect | Common |

| Production Capacity | High | Common |

Half-face respirators made by liquid silicone injection molding are higher than compression molding

The mold cost is different:

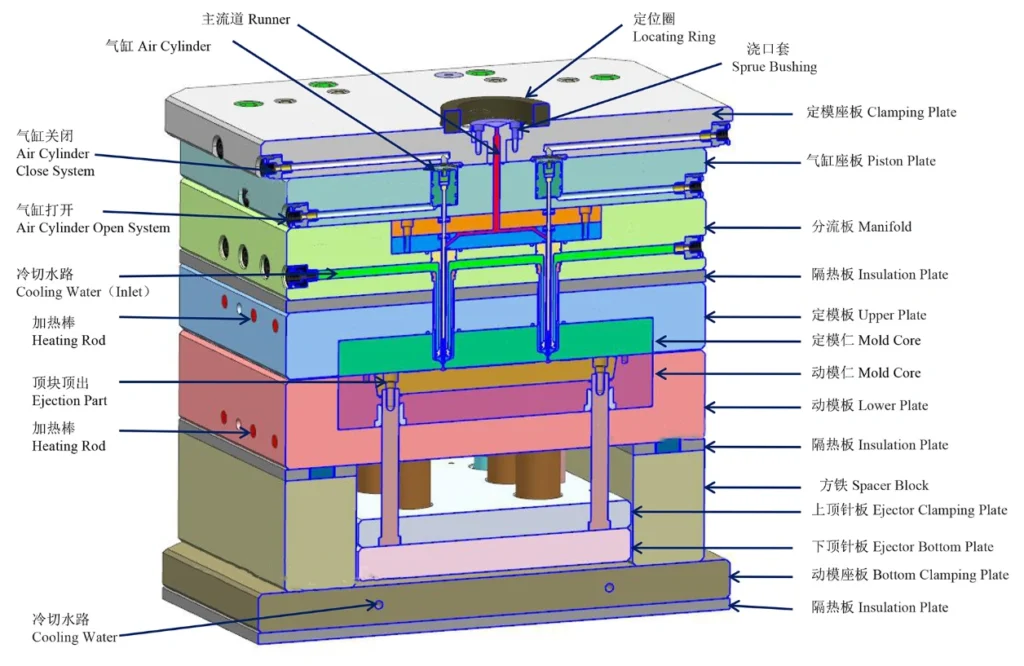

LIM mold cost is much higher than compression molding mold for face masks require more mold templates such as clamping plate, piston plate, manifold plate, insulation plate, spacer block, ejector clamping plate, ejector bottom plate, and bottom clamping plate, not similar to silicone compression molding that just needs an upper plate, mold core, and lower plate which mold structure is simple.

Silicone face mask unit cost is different:

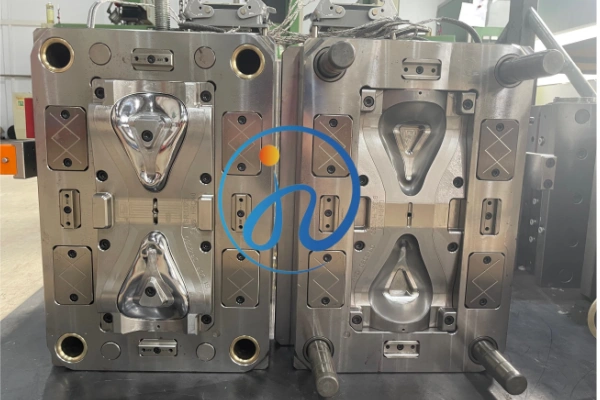

Regarding LIM molds, to save unit cost, generally, we use double-mold injection molding, 2 cavities for one mold. High automotive production can increase production efficiency which can decrease unit cost.

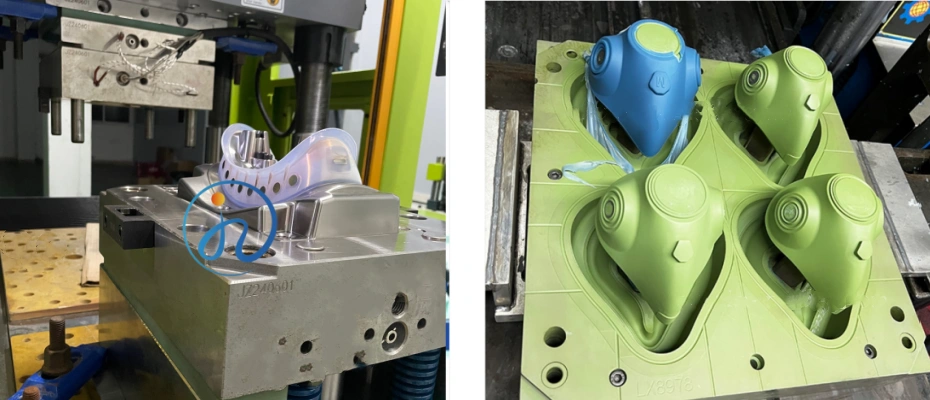

Half-face respirators’ quality is different: LSR injection molding can make high-precision silicone rubber products with very small parting lines, and nearly without burrs. It means LIM is more suitable for high strict quality requirements. So if you require large quantities and high-quality parts, the LIM is more suitable for you.

We Offer customized service: doing liquid silicone rubber mold and producing the final parts according to samples or 3D drawings.