When discussing liquid silicone rubber (LSR) and liquid injection molding (LIM), it’s important to understand that these terms refer to different but interrelated concepts in the realm of silicone materials and manufacturing processes. Below, we delve into the definitions, applications, and key differences between LSR and LIM.

1. Defining LSR and LIM

Liquid Silicone Rubber (LSR)

LSR is a high-performance elastomer known for its unique properties, such as flexibility, durability, and resistance to extreme temperatures. It is a two-component material that is mixed, cured, and molded into various products. Due to its biocompatibility, thermal stability, and electrical insulation properties. LSR is widely used across industries, including medical, automotive, consumer goods, and electronics.

Key Characteristics of LSR:

- Material Composition: Typically a two-part formulation consisting of silicone polymer and a catalyst or curing agent.

- Physical Properties: Offers excellent tensile strength, elasticity, and resistance to environmental factors such as UV radiation and chemicals.

- Versatility: Can be colored, textured, or blended with additives to enhance specific properties like flame retardancy or thermal conductivity.

Liquid Injection Molding (LIM)

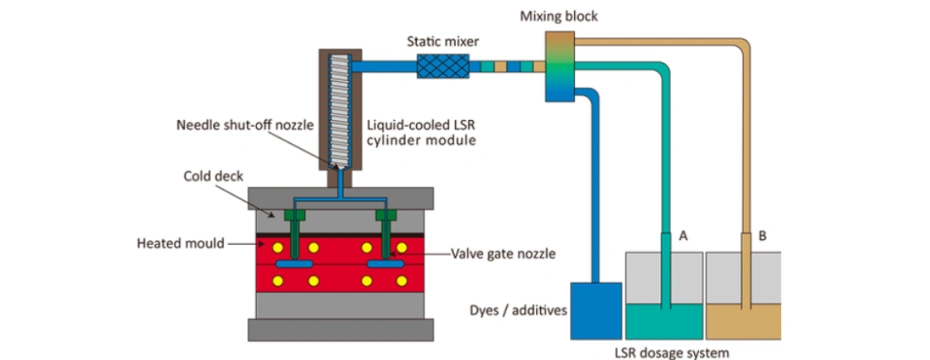

LIM refers to the process used to mold LSR into desired shapes and forms. It involves injecting the liquid silicone into a heated mold cavity, where it cures and solidifies into the final product. LIM is an automated process designed for precision and efficiency, often used for high-volume production of complex silicone parts.

Key Features of LIM:

- Process Automation: Typically involves computer-controlled machines for consistency and precision.

- Cycle Time: Shorter curing times compared to traditional molding techniques, making it suitable for mass production.

- Design Flexibility: Capable of producing intricate geometries and thin-walled components.

2. Key Differences Between LSR and LIM

While LSR refers to the material itself, LIM pertains to the process of molding this material. Below, we highlight the main distinctions between the two:

A. Nature and Definition

- LSR: A material; that is the raw, uncured form of silicone used for creating end products.

- LIM: A manufacturing method that describes how LSR is shaped and cured into finished goods.

B. Role in Manufacturing

- LSR: Acts as the feedstock for the LIM process.

- LIM: Utilizes LSR as its primary material to produce silicone parts and components.

C. Focus

- LSR: The focus is on material properties like flexibility, thermal resistance, and biocompatibility.

- LIM: The emphasis is on the efficiency, precision, and scalability of the molding process.

3. Advantages of LSR and LIM

LSR

- Durability and Resilience: Ideal for applications requiring longevity and resistance to wear and tear.

- Wide Temperature Range: Performs well in environments ranging from -50°C to 250°C (-58°F to 482°F).

- Biocompatibility: Frequently used in medical applications, such as implants and prosthetics.

- Customization: Can be tailored to meet specific functional and aesthetic needs.

LIM

- Efficiency: The automated process minimizes manual intervention and reduces production times.

- Precision: Achieves tight tolerances and consistent quality, even for complex designs.

- Scalability: Suitable for both small and large-scale production runs.

- Cost-Effectiveness: Reduces material waste and labor costs due to its automated nature.

4. Applications of LSR and LIM

LSR Applications

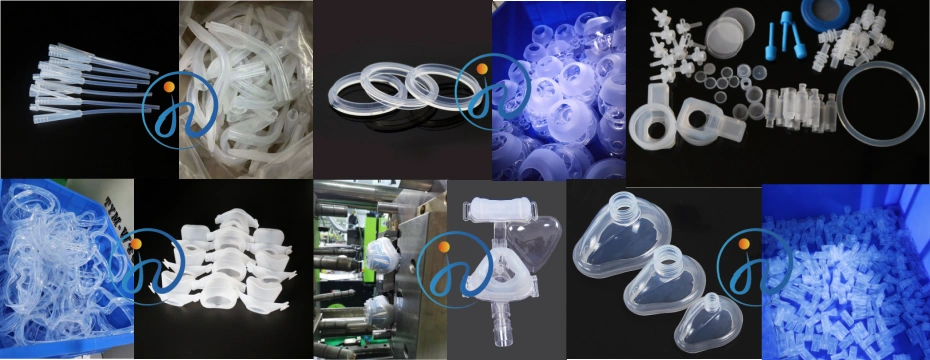

- Medical Devices: Catheters, seals, and syringes.

- Automotive: Gaskets, O-rings, and cable insulation.

- Consumer Products: Kitchenware, baby products, and wearable devices.

- Electronics: Keypads, seals, and connectors.

LIM Applications

- High-Volume Parts: Medical tubing, seals, and gaskets for automotive and industrial use.

- Complex Components: Products with intricate shapes and fine details, such as optical lenses and small electronic parts.

- Specialized Needs: Parts requiring consistent precision, such as components for aerospace and defense.

5. Challenges and Considerations

LSR Challenges

- Material Cost: LSR can be more expensive than other elastomers.

- Processing Requirements: Requires specific equipment and expertise for effective molding.

LIM Challenges

- Initial Investment: High upfront cost for machinery and molds.

- Maintenance: Requires regular calibration and maintenance of machines to ensure accuracy.

6. Choosing Between LSR and LIM

In practice, LSR and LIM are not mutually exclusive. Instead, they are complementary. The choice between them depends on the context:

- If the focus is on material properties (e.g., flexibility, temperature resistance), then LSR is the key consideration.

- If the emphasis is on the production process (e.g., speed, precision, scalability), LIM is the critical factor.

7. The Interplay of LSR and LIM in Modern Manufacturing

The relationship between LSR and LIM exemplifies how material science and process technology converge to enable innovation. For instance:

- Medical Devices: The biocompatibility of LSR, combined with the precision of LIM, ensures the production of safe and reliable components for healthcare applications.

- Consumer Electronics: LSR’s insulating properties, coupled with LIM’s ability to create intricate designs, support the production of durable and compact devices.

8. Conclusion

The distinction between LSR and LIM lies in their respective roles in the manufacturing ecosystem. LSR represents the material, with its inherent properties making it suitable for a wide range of applications. LIM, on the other hand, is the process that harnesses LSR’s potential to create high-quality, precision-molded parts.

By understanding their differences and complementary nature, manufacturers can make informed decisions to optimize their products and processes, achieving both performance and cost-efficiency in a competitive market.