Liquid Silicone Rubber (LSR) overmolding is a highly versatile manufacturing technique that has gained significant traction in the production of baby products. Overmolding involves molding one material (LSR) over another substrate, typically plastic or metal, creating a single integrated part. The unique properties of LSR and the precision of overmolding offer a wide array of benefits that make this method ideal for baby products, which demand safety, durability, and functionality. Here’s a detailed exploration of the advantages of LSR overmolding in baby products:

1. Safety and Non-Toxicity

Baby products must meet stringent safety standards, and LSR is inherently safe for use in applications involving direct contact with infants.

- Food-Grade liquid silicone rubber: LSR is often available in food-grade formulations, ensuring compliance with FDA and other global safety standards. It is free from harmful chemicals such as BPA, phthalates, and latex, which can pose health risks to babies.

- Hypoallergenic Properties: LSR does not irritate sensitive skin or trigger allergic reactions, making it ideal for pacifiers, teething rings, and bottle nipples.

- Odorless and Tasteless: Unlike some materials, LSR does not emit any odors or tastes, ensuring that baby products do not discourage use or interfere with feeding.

2. Soft-Touch Comfort

Baby products benefit from the soft and flexible nature of LSR, which provides a gentle, comfortable interface for babies.

- Enhanced Grip: The overmolding process enables the addition of a soft-touch layer to rigid components, improving grip and comfort. For example, sippy cups or baby spoons with LSR grips are easier for small hands to hold.

- Impact Absorption: The cushioning effect of LSR minimizes the risk of injury if a baby chews on or drops the product.

3. Durability and Resilience

LSR is highly durable and retains its properties over time, even under demanding conditions.

- Resistance to Wear and Tear: Baby products often endure chewing, pulling, and bending. LSR’s resilience to deformation ensures long-lasting performance.

- Heat and Cold Resistance: LSR can withstand extreme temperatures without losing its structural integrity. This property makes it suitable for bottle nipples, which need to endure sterilization in boiling water, and teethers designed for cooling in freezers.

- Chemical Resistance: LSR resists damage from cleaning agents, saliva, and other substances, ensuring that baby products remain safe and functional over extended use.

4. Hygienic and Easy to Clean

Maintaining cleanliness is a top priority for baby products, and LSR excels in this aspect.

- Non-Porous Surface: LSR’s non-porous surface prevents the accumulation of dirt, bacteria, and mold, promoting hygiene.

- Dishwasher Safe: Products made from or coated with LSR are typically dishwasher-safe, simplifying the cleaning process for parents.

- Sterilization Friendly: LSR is compatible with various sterilization methods, including steam, autoclaving, and UV exposure.

5. Design Flexibility

The versatility of LSR and the precision of overmolding open up a wide range of design possibilities for baby products.

- Complex Geometries: LSR’s flowability during molding allows for the creation of intricate designs and seamless parts, such as pacifiers or teething toys with integrated handles.

- Color Customization: LSR can be pigmented to produce vibrant, baby-friendly colors without compromising safety.

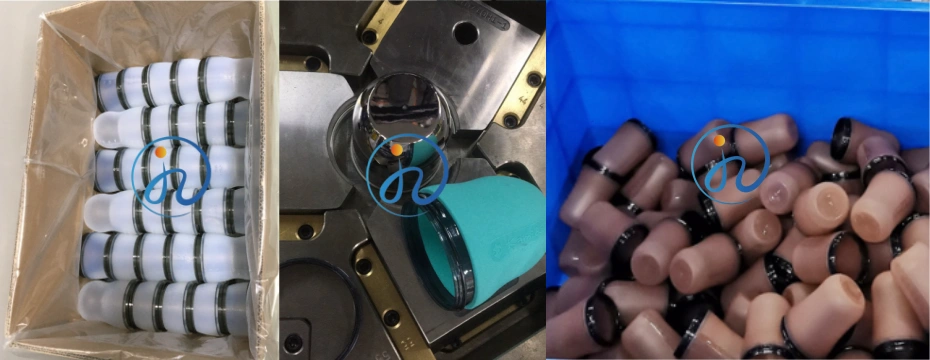

- Multi-Material Integration: Overmolding enables the combination of rigid and flexible materials in a single product, enhancing functionality and aesthetics. For instance, a hard plastic baby bottle can feature an LSR nipple and grips.

6. Enhanced Bonding

One of the key advantages of LSR overmolding is its excellent adhesion to various substrates.

- Chemical Bonding: LSR forms a strong, permanent bond with many materials, including plastics, metals, and thermoplastics, without requiring adhesives.

- Leak-Proof Seals: Overmolded LSR creates watertight and airtight seals, making it ideal for products like feeding bottles, food containers, and spill-proof cups.

7. Eco-Friendliness

Parents increasingly prefer eco-friendly baby products, and LSR aligns with this trend.

- Recyclability: LSR is recyclable and contributes to sustainable manufacturing practices.

- Longevity: The durability of LSR reduces the need for frequent replacements, minimizing waste.

8. Cost-Effectiveness

While the initial tooling cost for LSR overmolding can be high, the long-term cost savings are substantial.

- Reduced Assembly Requirements: Overmolding eliminates the need to assemble multiple components, reducing labor costs and production time.

- Minimized Defects: The precision of overmolding leads to fewer production errors and waste, lowering overall manufacturing costs.

9. Improved Functionality

LSR overmolding enhances the functionality of baby products through innovative design and material properties.

- Temperature Indicators: LSR can incorporate color-changing features to indicate temperature changes, adding an extra layer of safety to baby feeding products.

- Chewable Surfaces: For teething products, LSR provides a durable yet soft surface that soothes sore gums without risk of damage.

10. Appealing Aesthetics

The smooth finish and vibrant colors achievable with LSR make baby products visually appealing.

- Seamless Integration: Overmolding creates a sleek, polished look by eliminating seams and joints.

- Customization Options: The ability to mold logos, patterns, or textures directly into the product enhances branding and differentiation in the market.

Applications in Baby Products

- Feeding Accessories: Bottle nipples, spill-proof cups, and soft-grip utensils benefit from LSR’s flexibility and safety.

- Pacifiers and Teething Toys: LSR provides chewable, durable, and hygienic surfaces ideal for these applications.

- Bath Products: Overmolded LSR enhances grips on baby bathtubs and bath toys.

- Medical Devices: Baby thermometers and nasal aspirators utilize LSR for its biocompatibility and ease of sterilization.

Conclusion

Liquid Silicone Rubber overmolding combines the best attributes of LSR and precision manufacturing, making it an unparalleled choice for baby products. Its safety, durability, and design versatility meet the unique demands of this market, while its cost-effectiveness and eco-friendliness appeal to manufacturers and consumers alike. As technology advances, the potential for innovative LSR overmolded baby products will only continue to grow, providing safer, more functional, and aesthetically pleasing solutions for parents and their little ones.