Impact of Liquid Silicone Rubber (LSR)

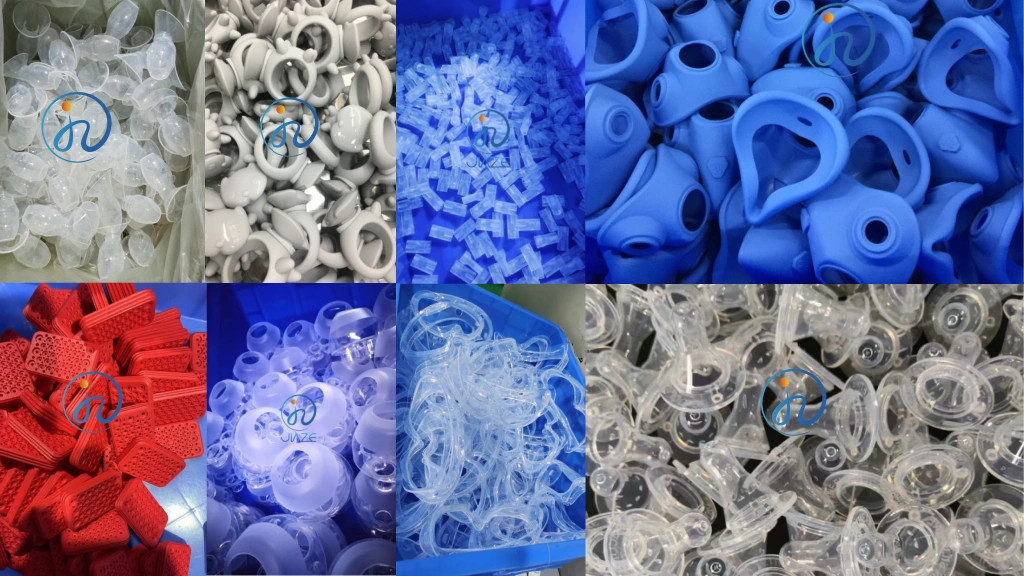

As a seasoned expert in manufacturing, I’ve witnessed the remarkable benefits of LSR on diverse projects. Its unique properties make LSR an ideal choice, enhancing both efficiency and quality across various applications.

Benefits of LSR

From precision and consistency to chemical resistance and automation ease, the benefits of LSR for your project are substantial. Its adaptability, durability, and cost-effectiveness make it a preferred material in industries ranging from healthcare to automotive and beyond.

Advantages of Liquid Silicone Rubber (LSR) in Manufacturing

As a specialist in the field of manufacturing, I have actually experienced firsthand the transformative influence of Liquid Silicone Rubber (LSR) in different manufacturing processes. The special buildings of LSR make it a perfect option for a vast array of applications, using numerous advantages that improve both the efficiency and high quality of making tasks.

Accuracy and Consistency

One of the most significant benefits of utilizing LSR is its capability to get rid of high accuracy and uniformity. LSR’s low viscosity permits it to fill complex molds successfully, guaranteeing that also the most complicated layouts are reproduced with accuracy. This precision is necessary for industries where minute details can influence the overall functionality of the product.

Wide Temperature Range

LSR products are understood for their capacity to stand up to extreme temperature levels, ranging from -60 ° C to 250 ° C. This large temperature level range makes LSR a superb choice for items that need to endure severe environments, preserving their integrity and efficiency without degradation.

Resistance to Chemicals and UV Radiation

One more advantage of LSR is its remarkable resistance to a selection of chemicals, oils, and UV radiation. This resistance makes sure that LSR products keep their residential properties and appearance in time, even when subjected to challenging problems. This longevity is especially important in markets such as automotive and medical care.

Ease of Automation

The LSR shot molding procedure is very automated, which minimizes labor expenses and enhances production efficiency. The automation capacity of LSR production allows for high-volume manufacturing with very little human treatment, ensuring consistent quality and reducing the possibility of errors.

Security and Environmental Benefits of LSR

Safe and Hypoallergenic Properties

One of one of the most engaging security advantages of Liquid Silicone Rubber (LSR) is its non-toxic and hypoallergenic nature. This makes LSR an excellent material for products that enter into direct contact with the human body, such as medical tools, child products, and wearable modern technology. The product is devoid of harmful chemicals and allergens, guaranteeing that it does not create irritation or negative responses.

Warmth and Chemical Resistance

An additional substantial benefit of LSR is its remarkable resistance to severe temperatures and various chemicals. LSR can withstand both high and reduced temperatures without degrading, making it ideal for applications in harsh settings. Furthermore, its chemical resistance makes certain that it continues to be secure and safe also when subjected to aggressive materials, additionally enhancing its safety account.

Environmental Sustainability

From an ecological point of view, LSR stands out as a result of its environment-friendly features. LSR is a sustainable material due to the fact that it is highly durable and has a long life span, minimizing the demand for frequent replacements. Furthermore, the production process of LSR creates minimal waste, and the material itself is recyclable, adding to a reduced ecological impact.

Conformity with Safety Standards

Products made from LSR frequently fulfill or exceed strict safety and governing criteria. This compliance is important for sectors such as health care, automobile, and customer products, where security is vital. By utilizing LSR, makers can ensure that their products stick to the highest possible safety and security criteria, offering tranquility of mind to both producers and end-users.

Fire Resistance

LSR additionally offers exceptional fire resistance, which is an essential security function for lots of applications. The material is naturally flame-retardant and can self-extinguish, reducing the risk of fire dangers. This building makes LSR specifically important in sectors where fire safety is a top concern, such as in electric and digital parts.

Applications of LSR in Various Industries

Liquid Silicone Rubber (LSR) is a versatile material that uses countless benefits for a large range of sectors. Its special residential or commercial properties make it an ideal selection for varied applications, from medical care to automobiles. Below, I will detail a few of the crucial sectors where LSR is making a significant influence.

Medical Care and Medical Devices

In the medical care field, LSR is highly valued for its biocompatibility and sanitary homes. It is generally made use of in the production of medical tools such as catheters, seals, and respiratory masks. The material’s resistance to bacteria and ease of sterilization makes it an outstanding choice for medical applications.

Automotive Industry

The automotive industry gains from LSR’s durability and thermal security. Parts such as gaskets, seals, and electrical connectors are typically made from LSR as a result of their ability to withstand extreme temperature levels and severe settings. This guarantees dependability and long life in car efficiency.

Consumer Electronics

LSR is frequently utilized in consumer electronics for components that call for accuracy and adaptability. Keypads, switches, and ports benefit from LSR’s outstanding tactile feeling and resistance to damage, improving the user experience and product lifespan.

Food and Beverage Industry

In the food and beverage market, LSR is used for producing molds, seals, and other parts that enter contact with food. Its non-toxic nature and ability to preserve integrity at different temperatures make it appropriate for food handling and packaging applications.

Industrial Applications

Industries associated with production and production use LSR for its chemical resistance and mechanical homes. It is used in seals, gaskets, and other elements that need constant efficiency and sought-after conditions.

| Industry | Applications |

|---|---|

| Medical care | Catheters, Seals, Respiratory Masks |

| Automotive | Gaskets, Seals, Electrical Connectors |

| Consumer Electronics | Keypads, Buttons, Connectors |

| Food and Beverage | Molds, Seals, Packaging Components |

| Industrial | Seals, Gaskets, Mechanical Components |

To conclude, the benefits of LSR across various industries are substantial and impactful. Its adaptability, combined with its durable residential or commercial properties, makes it a necessary material for advancement and effectiveness in contemporary production.